Do your car seat covers meet the highest safety standards?

Complies with International Safety Standards.

AUSTRALIA'S SAFEST SEAT COVERS

COMPUTERISED AIRBAG SupaSeam SEWING MACHINE

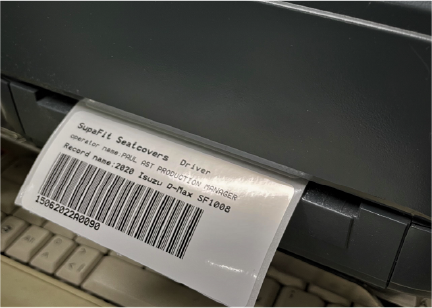

INDIVIDUAL BARCODE RECORD AND TRACEABILITY

ERROR LOCK-OUT FUNCTIONQUALITY ASSURANCE

EXTENSIVE INDEPENDENT TESTING - DESIGN, CONTROLS & PROCESS

GUARANTEED CORRECT & SAFE DEPLOYMENT OF EVERY AIRBAG SupaSeam

INDEPENDENTLY TESTED

AIRBAG SUPASEAM

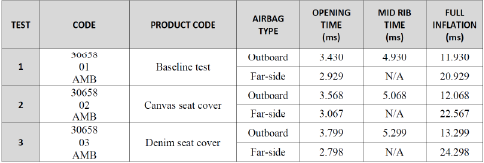

Independently tested by APV-T Tech Centre (NATA Accreditation No. 593), including hot +85deg and cold -35deg temperatures.

ADR72/00 Vehicle Standard (Australian Design Rule 72/00 – Dynamic Side Impact Occupant Protection) 2005 certified compliant.

INDUSTRY LEADING TECHNOLOGY

Engineered, purpose built, specialised German Adler 550-867 sewing station as used by international automotive car manufacturing industry.

It’s key features provide:

- Fully controlled, documented high-quality airbag SupaSeam.

- Individual bar-code & record for each airbag SupaSeam.

- Documented and monitored production data. Permanent computer controlled stitch length, tension & speed ensure quality & consistency of every SupaSeam manufactured.

- Error lock-out function ensures each & every airbag SupaSeam is within set parameters.

AIRBAG SPECIFIC THREADS

- Specialist polyester continuous filament, unbonded thread – made for stronger, high SupaSeam strength & perfect stitch formation.

- Purpose specific thread with stringent quality controls and tight manufacture specifications.

- Threads made from continuous filament provide greater uniformity, than natural fibre threads used within the industry.

Unique Design

SupaFit Seat Covers tested SupaSeam stitched airbag design provides:

- Unobstructed direct contact of deploying airbag against seam.

- Design ensures nil directional diversion of deploying airbag.

- Guaranteed safe deployment of seat airbag.

- Manufacturing controls in place to ensure consistency of EVERY airbag SupaSeam produced.

AIRBAG SUPASEAM IDENTIFICATION

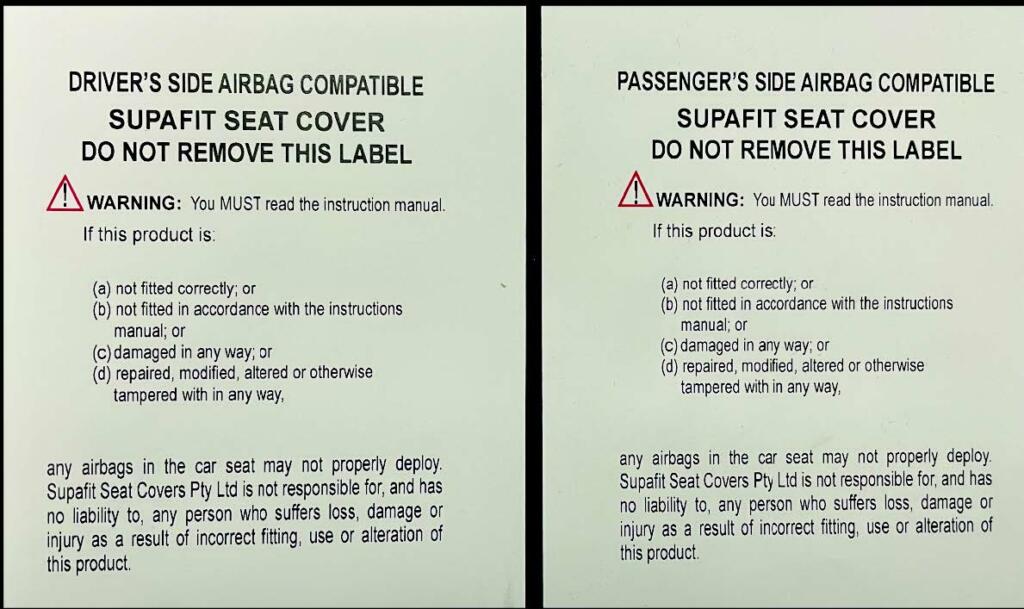

SRS Airbag Tag

Every airbag compatible SupaFit Seat Cover is easily identified with industry standard SRS Airbag Tags sewn into the SupaSeam, and displayed prominently. Additionally, every seat cover has the SupaFit Seat Cover label displayed as part of our quality control processes.

SupaFit Seat Covers Fitment Label

Seat fitment labels are sewn into the rear of each airbag seat (as per OEM seat covers):

- Identify correct seat cover for seat,

- Warning requirement of correct seat cover for vehicle seat,

- Warning requirement of correct fitment.

- Warning requirement seat cover must be free of damage or repairs.

AIRBAG SUPASEAM IDENTIFICATION

Bag Insert

- Identification & confirmation by part number, description, material and colour.

- Washing care instructions.

- Fitting instructions.

LEGISLATIVE REQUIREMENTS

Best practice seat cover pattern design procedures should involve removal of seat from vehicles for:

- Accurate identification of placement of seat airbag module within seat.

- Accurate identification of a location of seat airbag SupaSeam.

- Accurate identification and consideration of any components or safety features impacted by fitting of seat covers.

Within Western Australia, the Motor Vehicle Repairers Act 2003, (the Act) (s.5) states requirement that an individual and/or business must be registered as a licenced repairer where they are “undertaking any type of work that is removing or refitting any component on or to a motor vehicle”.

Each and every seat cover is designed by a team of Qualified Automotive Trimming Technology Tradespersons, each with 25+ years industry experience.

THE AIRBAG COMPATIBLE SEAT COVER

Fact

SRS airbags were first installed in a passenger car in 1980 - in a Mercedes-Benz S-Class.

Fact

Holden were the first local manufacturer to introduce a driver’s airbag to Australian motorists in 1993 in the VR Commodore.

Fact

An airbag deploys in between 10 to 30 milliseconds, half the time it takes to blink.

Fact

Not all airbag compatible seat covers are created equal.

DON’T COMPROMISE ON SAFETY

MILLISECOND PRECISION

DON’T COMPROMISE ON SAFETY

ALTERNATE METHODS

Airbag Hole

- Opening allows airbag to deploy through the space provided only.

- When seat cover shifts on seat, airbag opening moves out of alignment resulting in airbag

deploying BEHIND the seat cover. - Inferior upholstery protection with opening not providing full enclosed defence from dust & dirt.

- Only suitable on cartridge type airbags

Open Side with Flap Cover

- Opening may allow airbag to deploy.

- Flap laying between opening and seat airbag seam is an OBSTRUCTION which may delay deployment speed and correct airbag deployment direction.

- Airbag opening lengths fall short of OE seat manufacturer’s airbag seam design.

- Inferior upholstery protection with opening not providing full enclosed defence from dust & dirt.

FULL “LIGHT THREAD’ STITCHED SEAM

Use of a ‘light’ thread as an airbag seam is based on a theory light weight / finer thread will create a weak point along the seat cover stitching therefore deemed suitable as an airbag seam. Popular in cheap imported seat covers, motor trimmers & businesses who have failed to invest in research, testing and equipment.

- Use of ‘light thread’ only,

- No additional controls and specification used ie tension, etc.

- Often have no labeling or manufacture information for liability.

Open Side with Flap Cover & Securing Velcro

- Opening may allow airbag to deploy.

- TWO (2) OBSTRUCTIONS that may delay the safe & correct deployment of seat airbag.

* VELCRO* securing opening

* Flap laying between opening and seat airbag seam - Airbag opening lengths fall short of OE seat manufacturer’s airbag seam design.

- Limited controls on velcro size and strength.

- Limited control

FULL VELCRO* SEAM

- Opening may allow airbag to deploy.

- FULL length VELCRO* airbag seam may be a significant OBSTRUCTION to the safe & correct deployment of the seat airbag.

- Sewing process has limited control to it’s positioning of, or width and brand of Velcro or Touch Tape.

- Limited ability to ensure consistency and reliability of sewn velcro airbag seam

VELCRO - DEFINITION

Hook-and-loop fasteners, hook-and-pile fasteners or touch fasteners consist of two components: typically, two lineal fabric strips (or, alternatively, round “dots” or squares) which are attached (sewn or otherwise adhered) to the opposing surfaces to be fastened. The first component features tiny hooks, the second features smaller loops. When the two are pressed together the hooks catch in the loops and the two pieces fasten or bind temporarily. When separated, by pulling or peeling the two surfaces apart, the strips make a distinctive “ripping” sound. Velcro is traditionally used in the transportation industry to fasten & secure in place seat trim, carpeting & headlinings, etc. Velcro’s most distinguishing feature as a product is it’s strength in securing.

Please note that other velcro manufacturers would not give tear strengths due to many factors that could adversely affect consistency *Velcro Hook 88 & 1000 Loop Closure Performance.

Seat covers designed with Velcro for all, or part of, an airbag seam- however will not pass the stringent NATA accredited APV-Tech testing regime utilising all the necessary controls and calibrations – as those used in the design & manufacture of the SupaFit Seat Cover product.

TEST RESULTS

PROVEN AND TESTED

SupaFit Seat Covers have manufactured 100,000’s of seat covers that have been fitted to vehicles through-out Australia since 2012. Nothing has made us prouder than hearing from those who have put our airbag compatible seat covers to the test, and been able to contact us and thank us.

AUSTRALIAN MADE

Proudly certified Australian Made (Licensee ID No.: 11003), SupaFit Seat Covers sources all it’s materials Australian Made from Australian manufacturers & suppliers.

Denim

Our 100% cotton – twill Denim (not associated with other products on the market), was specially developed for us, and recommended for the mining industry. Introduced in the late 1990s it is the original specification for mining vehicles (including BHP & Rio Tinto) and fleet vehicles, predominately for its intrinsic electrostatic properties.

Benefits & Safety Advantages of Denim:

- 100% cotton is a natural breathable fibre which allows the heat to disperse from the fabric, unlike polyester materials that hold in the heat and can burn the skin, making it perfect for the Pilbara region.

- Free of Chemicals

- Hypo-allergenic and non irritant to skin.

- Static Free – eliminating static charge build up associated with polyester woven fabrics. A particular safety concern to risk environments for example, shot firer workers.

AUSTRALIAN MADE

Canvas

Our 15oz Military Grade canvas makes it one of the heaviest weighted/durable products on the market. 100% waterproof, UV stabilised, mildew & mould resistant make it the most durable option for the most harshest working environments.

Warranty

100% Satisfaction Guarantee

SupaFit Seat Covers warrants that it will, at its option, replace or repair each product that you purchase which, during the Warranty Period, has a defect in materials or workmanship under normal use and conditions.

AUSTRALIAN JOBS

SupaFit Seat Covers is a Perth based employer of 75+ Australians, comprised of our:

- Design and Research team (8 Qualified Motor Trimmers).

- Production & Manufacturing team.

- Sales team (WA, VIC & QLD based).

- Administration & Logistics teams.